3D Printed Nuclear Safety Valves

Take the United States as an example. Since 2007, the United States has put into operation 24 reactors. In order to ensure the safe operation of these factories and avoid the recurrence of past disasters, Americans maintain and repair them frequently. However, KAERI's team found that some safety-critical components were in short supply, such as chemical and volume control system (CVCS) valves for reducing core pressure.

Specifically, CVCS is used to perform fluid supply or flow tasks in the reactor. Although it can be deployed in other places, safety valves must always meet certain standards. For example, nuclear components must pass the water pressure, operation and flow test before deployment, and it has been proved that it is difficult to create flexible components as required.

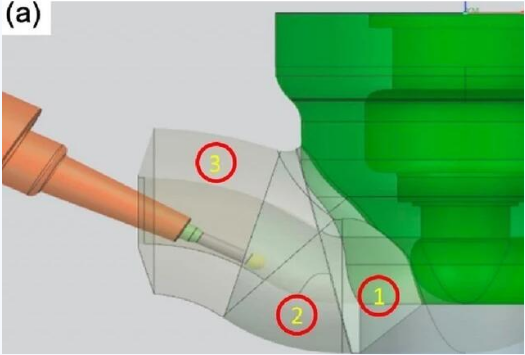

The valve consists of three independent parts.

According to KAERI scientists, metal 3D printing alone is not enough to replace traditional production to manufacture nuclear spare parts. However, by combining directional energy deposition (DED) technology with 5-axis CNC machining, the team found that they were able to make replicas with the extremely high accuracy required.

Researchers' chromium and nickel-based valves have 3D printed valve bodies, bonnets and cages. After assembly, the 300mm device is strictly evaluated. During the pressure test, it was found that the layer boundary of the equipment acted as the focus of residual stress, which reduced the strength by 7 to 8%.

Similarly, when CVCS is post-treated in the HIP at 1100℃, its integrity is reduced by 33%, which is 18% higher than that of traditional valves. However, in terms of stable performance and its "fatigue limit", the tensile strength of the equipment made of this kind of additive is 202.6 MPa, which is superior to that of commercial products.

Overall, the research team concluded that despite the reaction to heat treatment, the constant strength of its additional valve was enough to make it finally used. Considering that the CECS of this group copied the components of category 1, the nuclear regulatory agency of the International Atomic Energy Agency will classify them as "the parts whose failure will lead to serious consequences". The strength of 3D printing parts is really highly praised.