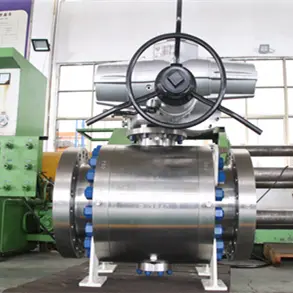

Ball Valve

Ball valves supplied by Topper are durable and superior, including cast steel ball valves, fully weld ball valves, top entry ball valves, high temperature ball valves, cryogenic ball valves and three way ball valves.

The application of ball valves is very extensive, with the number of related products being continuing to expand. And they have played an important role in petroleum, chemical, electric power, water conservancy, urban construction and other fields nowadays.

With fire-safe, anti-static and blow-out proof features, ball valves are generally used in pipelines to cut off and adjust the use of media, which are capable of flexibly switching off and distributing media, and changing their flow directions. The sealing surface of a ball valve is usually in a closed state with the sphere, so it is not easy to be eroded by the medium. Ball valves are easy to operate with a simple and compact structure and can be widely applied in some special working conditions with water, natural gas, acid, solvent and so on.

Forged Steel Ball Valves are suitable for petroleum, chemical, power and other industries and applied to pipelines, tanks and containers as opening and closing devices. Forged ball valves have small fluid resistance with the full flow design and are convenient to be installed and disassembled. Featuring good fire-proof property, they are able to ensure reliable sealing effects in the case of accidental fire and prevent sealing surfaces from being eroded by media.

Body Material: Forged Carbon Steel, Stainless Steel, Alloy Steel.

Normal Diameter: 2 - 24 Inch (DN15 - DN600).

End Connection: BW, Flanged.

Pressure Range: Class 600 - 2500 LB (PN100 - PN420).

Operation: Lever, Gearbox, Electric, Pneumatic, Electro-Hydraulic Actuator, Gas-Over-Oil Actuator.

Working Temperature: -46℃ - +200℃.

Cast steel ball valves are a series of ball valve products with many types, having a very wide range of applications in petroleum, long-distance pipeline, chemical, electric power and other industries. They are mainly used in pipelines to cut off, distribute and change the flow directions of media. With a cast steel body, this type of ball valve can be quickly opened and closed by manually rotating the handle 90 degrees. Simple structure, good sealing, relatively small volume and driving torque, and being easy to make open-close operation are all the characteristic features of them. What's more, cast steel ball valves are not only suitable for water, solvent, acid, natural gas and other general media, but also proper for poor conditions, like hydrogen peroxide, methane and ethylene.

Product Feature: Cast Steel.

Body Material: Carbon Steel, Stainless Steel, Alloy Steel.

Normal Diameter: 2 - 60 Inch (DN50 - DN1500).

End Connection: BW, RF Flanged.

Pressure Range: 150 - 2500 LB (PN16 - PN420).

Operation: Lever, Gearbox, Electric, Pneumatic, Electro-Hydraulic Actuator, Gas-Over-Oil Actuator.

Working Temperature: -46℃ - +200℃.

Fully welded ball valves have superior quality, higher performance and longer service life than cast steel ball valves. They have been widely used in various fields, including city gas and heat supply, petrochemical, shipbuilding, steel, pressure regulating station, power plant and other kinds of pipeline equipment. With a plastic-sprayed surface, fully-welded ball valves own compact structures and aesthetic appearances. And due to their welded bodies, these ball valves are lightweight and easy to be insulated.

Features:

1. Double Block and Bleed.

2. Standards to EN 12516, DIN 3357-1.

3. Fire Safe, Anti-static, Stem Blow-out.

4. Optional Locking Device and Position Indicator.

5. Size Ranges: 1/2 - 16 Inch (DN15 - DN400).

6. Pressure Ratings: ASME Class 150 - Class 900 (PN10 - PN150).

7. Standard Materials Ranges: Cast Carbon Steel, Stainless Steel, Alloy Steel, etc.

With the design based on the fixed type, the upper part of top entry ball valves have bonnets, and spheres, sealing rings and valve seats are all installed from the top. The stem is connected with the sphere, eradicating the chance of loosening or being hauled out. It's easy to check and maintain top entry ball valves fitted on pipelines, which greatly saving time and cost. And they are mainly aimed at highly corrosive media.

Size Ranges: 1/2 - 20 Inch.

Pressure Ratings: ANSI Class 150 - 2500 LB

Standards Compliance: API 6D, BS 5351, ASME B16.34, DIN 3202 or equivalents.

Materials: Cast Carbon Steel, Stainless Steel, Duplex or Other Specials.

Ends Connections: Flanged R.F, RTJ, Welded.

Optional Locking Device or Stem Extension.

ASME B16.34, API 6D, API 6A, API 607 and API 6FA, NACE MR 0175.

The main characteristics of high temperature ball valves are metal seals and a wide applicable temperature range. Generally speaking, the thermal expansion coefficients of many metals have no significant difference, which can be adjusted through proper choice to alleviate the deformation due to the disparity in temperatures. With the combination of the good-control feature of ball valves and butterfly valves, high temperature ball valves can be used as control and shut-off valves.

Size Ranges: 1/2 - 40 Inch.

Pressure Ratings: ANSI Class 150 - 2500 LB.

Standards Compliance: API 6D, BS 5351, ASME B16.34, DIN 3202 or equivalents.

Materials: Cast Carbon Steel, Stainless Steel, Duplex or Other Specials.

Ends Connections: Flanged R.F, RTJ, Welded or Victaulic.

Optional Locking Device or Stem Extension.

Optional Direct Mounting to ISO 5211.

Full Port or Regular Bore.

Double Block and Bleed.

Cryogenic ball valves, with flexible switches and reliable sealing, are suitable for the storage and transportation equipment of low-temperature liquid. They can also be used in other cryogenic and cool media systems, such as ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas and so on. Cryogenic ball valves generally adopt flange or welded connections. These valves are light in weight and small in size, ensuring the application in ultra-low temperatures and reducing heat losses. In most cases, the bodies and plates of cryogenic ball valves are made of cryogenic carbon steel whose rigidity, toughness and processing characteristics will improve the performance of ball valves.

Cryogenic ball valves are available in types of two-piece split body & three-piece bolted body. They are designed and manufactured to the updated international standards API 6D, ASME B16.34, BS 5351 or equivalents with standard fire-safe, anti-static and stem blow-out proof features.

Three way ball valves have T and L types, which are suitable for different production processes. T-pattern valves can connect the other two channels, flexibly controlling the separation and combination of media in pipelines. L-pattern valves can only connect two pipelines that are mutually orthogonal instead of maintaining the connectivity of the third pipeline at the same time, playing a distributional role. Three-way ball valves adopt an integrated structure with few flange connections and high reliability, which can be opened and closed quickly.

Product Feature: 3 Way Ball Valves.

Body Material: Carbon Steel, Stainless Steel, Alloy Steel.

Normal Diameter: 2 - 60 Inch (DN50 - DN1500).

End Connection: BW, Flanged.

Pressure Range: 150 - 2500 LB (PN16 - PN420).

Operation: Lever, Gearbox, Electric, Pneumatic, Electro-Hydraulic Actuator, Gas-Over-Oil Actuator.

Working Temperature: -46℃ - +200℃.