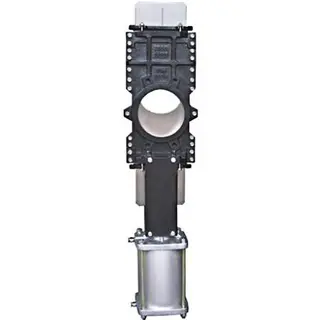

Gate Valve

Gate valves are one of the most common open-close valve products, using the gate to connect or cut off the medium in the pipeline. What's special about gate valves is that they can only be fully opened and fully closed. When this type of valve is fully opened, the flow resistance of the medium in the valve channel is almost zero so that the opening and closing of gate valves will be very labor-saving. However, the distance from the gate to the sealing surface is far, with the time of opening and closing being long.

Gate valves easily adapt themselves to the environment, which can be applied in high-temperature, low-temperature, high-pressure and low-pressure conditions. Due to the need for relatively high sealing performance and small flow resistance, it is appropriate to choose gate valves to use in the steam pipelines and large-diameter water supply pipelines.