Abstract

This article outlines the operating principles and applications of three-way ball valves and proposes an effective modification solution. By redesigning the valve core from a floating to a fixed type and replacing the dual-seat configuration with a quad-seat design, longstanding issues of jamming and leakage in polymerization reactor three-way ball valves were effectively resolved, resulting in significant operational improvements. The 1 million t/a PVC project at the Second Chemical Branch of Shaanxi Beiyuan Chemical Group Co., Ltd. (hereinafter referred to as Shaanxi Beiyuan Second Branch) utilizes Japan’s Chisso 108 m² polymerization reactor technology. Due to the complexity of PVC production, the high precision required, and strict automation standards, pneumatic three-way ball valves are essential for reducing installation costs, saving space, and ensuring reliable process control. In this project, a total of 130 pneumatic three-way ball valves were installed, including both T-type and L-type configurations, to meet specific process requirements. However, after system commissioning, the valves—especially the L-type—often failed to meet design expectations, exhibiting issues such as sticking, functional failures, and severe internal and external leakage. These issues jeopardized production safety, lowered product quality, and limited the plant’s capacity expansion. A thorough failure analysis was performed, followed by nearly a year of experimental retrofitting. Initial attempts—such as replacing valve seats and repacking the stuffing box—did not resolve the problems. The breakthrough solution involved converting the valve core from a floating to a fixed design and upgrading the valve from a dual-seat to a quad-seat configuration. The modifications proved highly effective, stabilizing the production system, enabling long-term continuous operation, reducing maintenance costs, and significantly enhancing production efficiency.

A pneumatic three-way ball valve is a rotary valve operated by a pneumatic actuator. Rotating the ball 90° enables flow direction switching, while a 180° rotation allows for switching, diverting, or combining the flow of the medium.

Pneumatic three-way ball valves are widely used for diverting, merging, and switching the flow of media, with any pipeline able to function as an inlet or outlet. They are typically available in L-type and T-type configurations to accommodate various process requirements.

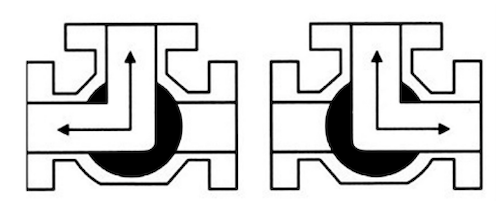

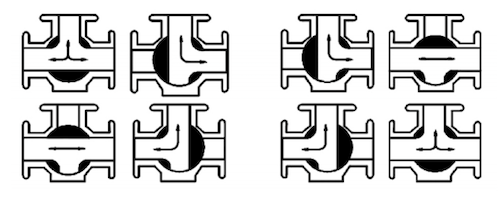

L-type pneumatic three-way ball valves are ideal for switching the flow direction of media and are typically used to connect two perpendicular pipelines. T-type pneumatic three-way ball valves are ideal for media diversion, merging, or flow direction switching. The T-shaped port can connect all three pipelines or any combination of two. While double-seat designs are most common, four-seat configurations can also be provided upon request. Figures 1 and 2 show the flow directions of L-type and T-type pneumatic three-way ball valves, respectively.

Figure 1: Flow diagram of an L-type three-way ball valve

Figure 2: Flow diagram of a T-type three-way ball valve

Pneumatic three-way ball valves are commonly fitted with electric valve positioners and controlled via a DC 4–20 mA signal and a 0.4–0.7 MPa air supply, enabling precise regulation of process parameters such as pressure, flow, temperature, and liquid level. Additionally, these valves include travel limit switches, solenoid valves, and pressure-reducing valves for on/off operation, along with two pairs of passive contact signals to indicate the valve’s open and closed positions.

Pneumatic three-way ball valves are extensively used in industries such as chemical processing, petroleum, textiles, power generation, food and pharmaceuticals, refrigeration, aerospace, and paper manufacturing. Their versatility and reliability make pneumatic three-way ball valves ideal for both general industrial applications and highly specialized processes.

Low fluid resistance – The resistance coefficient is comparable to that of a straight pipe of the same length, ensuring minimal pressure loss.

Compact design – Features a simple structure, small footprint, and lightweight construction for easy installation and seamless integration.

Tight and reliable sealing – Sealing surfaces are typically made from high-performance plastic materials, providing excellent leak-tight performance, even in vacuum applications.

Ease of operation – Quick 90° rotation from fully open to fully closed, enabling efficient manual, automated, or remote control.

Convenient maintenance – The valve’s straightforward design and typically movable sealing ring make disassembly and replacement simple and efficient.

Corrosion protection – When fully open or closed, the ball and valve seat sealing surfaces are isolated from the medium, preventing corrosion and ensuring long-term reliability.

Broad operating range – Available in sizes from a few millimeters to several meters, pneumatic three-way ball valves can be applied in systems ranging from high vacuum to high pressure.

Proper selection of three-way ball valves is critical for stable process control. In the polymerization section of Shaanxi Beiyuan Second Branch, improper choices regarding valve type, structure, design, and materials caused significant operational issues. These issues included valve sticking or complete failure to operate, severe internal leakage that compromised production requirements, and external leakage, primarily occurring between the stem and packing and at the gland seal. During operation, the valve core frequently shifted, causing the valve body to seize and resistance to increase, which in turn led to repeated damage or breakage of the rotating connection components and actuators.Furthermore, the clearance between the valve core and the valve seat decreased, damaging the valve core coating, deforming the valve seat, reducing surface smoothness, and compromising the sealing performance. Furthermore, the clearance between the valve core and the valve seat decreased, damaging the valve core coating, deforming the valve seat, reducing surface smoothness, and compromising the sealing performance. In extreme cases, the valve core itself became twisted and deformed. Failure analysis identified the primary cause as the original floating-type design of the three-way ball valve. In this configuration, the ball is supported by the valve seat, which bears the full weight of the valve core, resulting in uneven stress distribution. During switching, the process medium enters the valve cavity. Under sustained pressure and prolonged operation, the ball gradually shifts from its intended central position. Once this deviation reaches a critical threshold, internal leakage occurs, and the required torque increases as the misalignment worsens. This imbalance hinders proper valve operation, accelerates coating wear at high-stress areas, and exacerbates internal leakage. Since the ball offset varies with each switching cycle, prolonged unbalanced pressure enlarges the gap between the valve core and valve seats, resulting in packing leakage. The increasing torque further leads to deformation of the valve stem and connecting sleeve, or even damage to the actuator. Moreover, the PTFE soft-sealed valve seat material presented additional challenges. Although PTFE can theoretically withstand temperatures up to 180 °C, exposure to 130–140 °C hot water caused its mechanical properties to degrade. Its hardness decreased, and it began to adhere to the ball surface, damaging the valve seat and resulting in severe internal leakage.

To address the previously identified issues with the Flowrve three-way ball valve, Shaanxi Beiyuan Second Branch commissioned the development of a fixed-shaft, four-seat, hard-sealed three-way ball valve. In this design, the ball remains fixed and coaxial with the valve stem during switching, ensuring stable and reliable operation. The main structural improvements are as follows:

(1) Fixed Valve Core Design

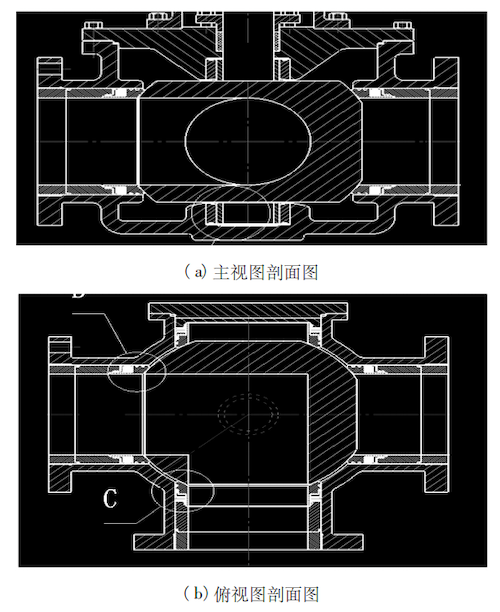

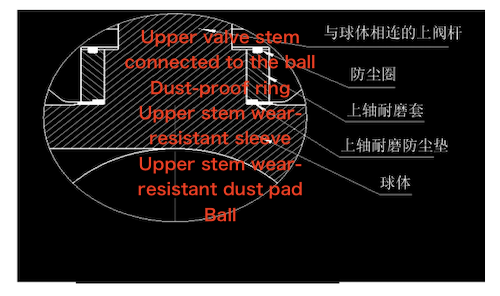

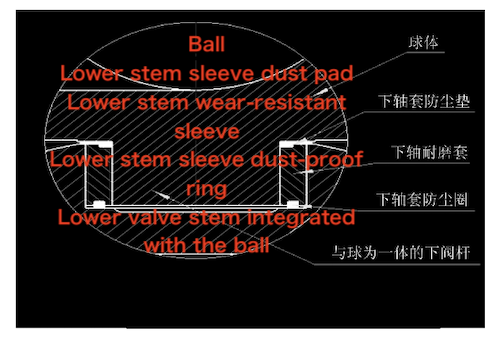

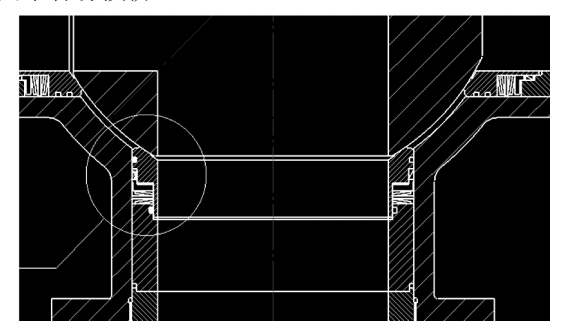

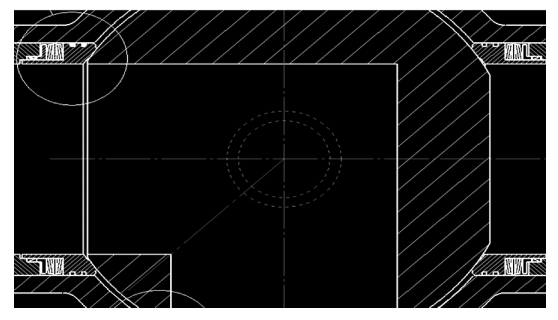

A fixed shaft is installed beneath the valve core and directly connected to it. Along with the upper valve stem, this shaft firmly secures the valve core, preventing displacement during operation (Figures 3–5).

Figure 3: Fixed valve core structure (main view and cross-section)

(a) front view section drawing (b) Top view section

Figure 4: Dustproof assembly of the upper valve stem

Figure 5: Dustproof assembly of the lower valve stem

(2) Four-Seat Structure Design

The innovative four-seat configuration comprises two main valve seats and two auxiliary valve seats, as shown in Figures 6 and 7. Each set of seats is designed to fulfill a specific function:

Main Valve Seats

Each main valve seat is supported by four stacked disc springs, delivering a high preload force between the valve seat and the ball. This increased contact pressure ensures reliable and effective sealing. To enhance sealing performance, a downstream valve seat design is implemented, preventing direct contact with the medium during operation and thereby extending the service life of the valve.

Auxiliary Valve Seats

The auxiliary valve seats apply a lower preload force than the main seats. Their primary function is to balance the ball, enabling smoother switching under pressure and ensuring more uniform force distribution.

Scraper Structure

All four valve seats feature a specially designed scraper structure, which removes residual material from the ball surface, keeps it clean, reduces wear, and ensures reliable sealing and smooth operation.

As a result, the sealing performance is reliable, valve operation is smooth, resistance is evenly distributed, and the ball surface is less susceptible to damage.

Figure 6: Schematic of the main valve seat structure

Figure 7: Schematic of the auxiliary valve seat structure

The connection between the valve body and the actuator is engineered to strengthen the valve stem, preventing damage from excessive torque during valve jamming. The valve stem is theoretically designed to transmit a torque of nearly 20,000 N·m, whereas the actual required operating torque is approximately 3,000 N·m. This means the stem can endure roughly six times the normal operating torque. The driving cylinder delivers a torque of 7,000–11,000 N·m, which is 2–3 times greater than the valve’s normal operating torque. All other torque-transmitting components are designed to meet the strength requirements of both the stem and the cylinder. Even under abnormal conditions, the valve can operate as programmed, preventing sticking or malfunction and greatly reducing the need for disassembly and maintenance. The valve seat and ball feature an adjustable preload design, using high-quality spring materials arranged in a multi-group configuration. The valve seat is installed from the flow channel and secured with a screw plug, enabling precise adjustment of both the preload pressure and the valve’s opening and closing torque. When the valve achieves Class VI leakage performance, the torque between the valve body and ball remains fully controllable. Furthermore, if minor leakage occurs due to wear over time, the valve seat does not need to be replaced. Tightening the valve seat cover resolves the issue, reducing maintenance costs while ensuring the valve’s precise control. The valve ball and seat base materials are 316 stainless steel, with the sealing surfaces made of a cobalt-based alloy. The upper and lower valve stems are also made of 316 stainless steel, with wear-resistant bushings embedded in the transmission areas to ensure that the rotating bearing sleeves can withstand pressure and wear. The plug and bushings, which are in long-term contact with the process medium, are likewise made of 316 stainless steel to enhance wear resistance. Additionally, the manufacturer strictly controls the grinding accuracy of the ball and valve seat, ensuring precise assembly and guaranteeing that the valve meets Class VI leakage standards. At the same time, the manufacturer must strictly control the grinding precision of the ball and seat to ensure accurate assembly and compliance with Class VI sealing standards. These design improvements have significantly enhanced the performance and reliability of the three-way ball valve. The nine valves currently in operation fully meet production requirements, playing a crucial role in increasing output and maintaining stable operation.

Through the analysis of valve failures in the polymerization section—initially by replacing valve seats and repacking, and subsequently by reconfiguring the valves from floating to fixed cores and from dual-seat to four-seat designs—Shaanxi Beiyuan Second Branch has sustained stable production over the past year. The modified valves no longer require frequent maintenance, reducing the workload for maintenance personnel, ensuring stable operation, and providing substantial economic benefits.