The application of ball valves is very extensive, with the number of related products being continuing to expand. And they have played an important role in petroleum, chemical, electric power, water conservancy, urban construction and other fields nowadays.

With fire-safe, anti-static and blow-out proof features, ball valves are generally used in pipelines to cut off and adjust the use of media, which are capable of flexibly switching off and distributing media, and changing their flow directions. The sealing surface of a ball valve is usually in a closed state with the sphere, so it is not easy to be eroded by the medium. Ball valves are easy to operate with a simple and compact structure and can be widely applied in some special working conditions with water, natural gas, acid, solvent and so on.

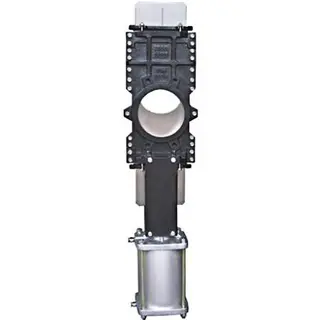

Gate valves are one of the most common open-close valve products, using the gate to connect or cut off the medium in the pipeline. What's special about gate valves is that they can only be fully opened and fully closed. When this type of valve is fully opened, the flow resistance of the medium in the valve channel is almost zero so that the opening and closing of gate valves will be very labor-saving. However, the distance from the gate to the sealing surface is far, with the time of opening and closing being long.

Gate valves easily adapt themselves to the environment, which can be applied in high-temperature, low-temperature, high-pressure and low-pressure conditions. Due to the need for relatively high sealing performance and small flow resistance, it is appropriate to choose gate valves to use in the steam pipelines and large-diameter water supply pipelines.

Globe valves are durable and easy to make and maintain, with the sealing surfaces of globe valves having small friction in the opening and closing processes and their opening height being short, which are suitable for all kinds of pressure conditions.

The main function of globe valves in chemical pipelines is to cut off or connect the fluid, which should be applied to situations that require frequent opening and closing. Globe valves have a better performance in flow regulation than gate valves, which can be used in water, steam and other pipelines. But globe valves can not be supplied to regulate the pressure and the flow for a long time, and it is improper to be used in pipelines that are easy to occur coking and precipitation, and have large viscosity. Otherwise, the sealing surfaces of globe valves may be eroded by media and the sealing performance will be destroyed.

Check valves should be installed on equipment, fittings and pipelines to stop media from being in a direction contrary to the current. Check valves are generally suitable for clean media instead of applying to media containing solid particles and great viscosity. And they are also widely used in petroleum, chemical, liquefied gas, boiler steam system, minerals, food, pharmaceutical, power generation, urban construction, municipal, and other fields, greatly improving the comprehensive use of energy efficiency.

There are many types of check valves designed and manufactured by Topper, such as lift check valves, swing check valves, wafer check valves, tilting disc check valves, etc.

Butterfly valves have multiple types and a wide range of applications. Topper provides reliable butterfly valve products, including lug concentric butterfly valves, wafer concentric butterfly valves and double offset butterfly valves. Generally speaking, butterfly valves can be used for our domestic water pipes, fire water pipes, circulating water pipes and sewage pipes to control and adjust the flow. In addition, they are also suitable for some powder, oil, mud and ventilation pipelines.

Forged Steel valves are the general name of all kinds of valves manufactured by forging. Forged valves are resistant to high temperatures and high pressures and are more durable than valves made in other ways. The structures of forged valves are very simple, which can be operated effortlessly and convenient to be installed and disassembled. Their effect on fluid resistance is very small, which is conducive to the flow of fluid and saves time on transportation to a certain extent.

Plug valves are mainly used to cut off the medium and change the flow direction of the medium in the pipeline. It is easy for them to adapt to multi-channel construction, which simplifies the design of pipeline system and reduces the number of connections required in the equipment. With small resistance and convenient open/close operation, the fluid can go through directly. Plug valves can be applied in oil field exploitation, natural gas field exploitation, branch pipe of pipeline transportation, refining and cleaning equipment, etc.

In the process of opening and closing, there is no friction between the core and the seat, thus avoiding energy losses and ensuring no leakage and long service life of plug valves. Plug valves own automatic sealing inspection system, double break switch and end cover on the top and bottom, which can be timely maintained and repaired. Generally, plug valves are suitable for occasions that require a high level of sealing.